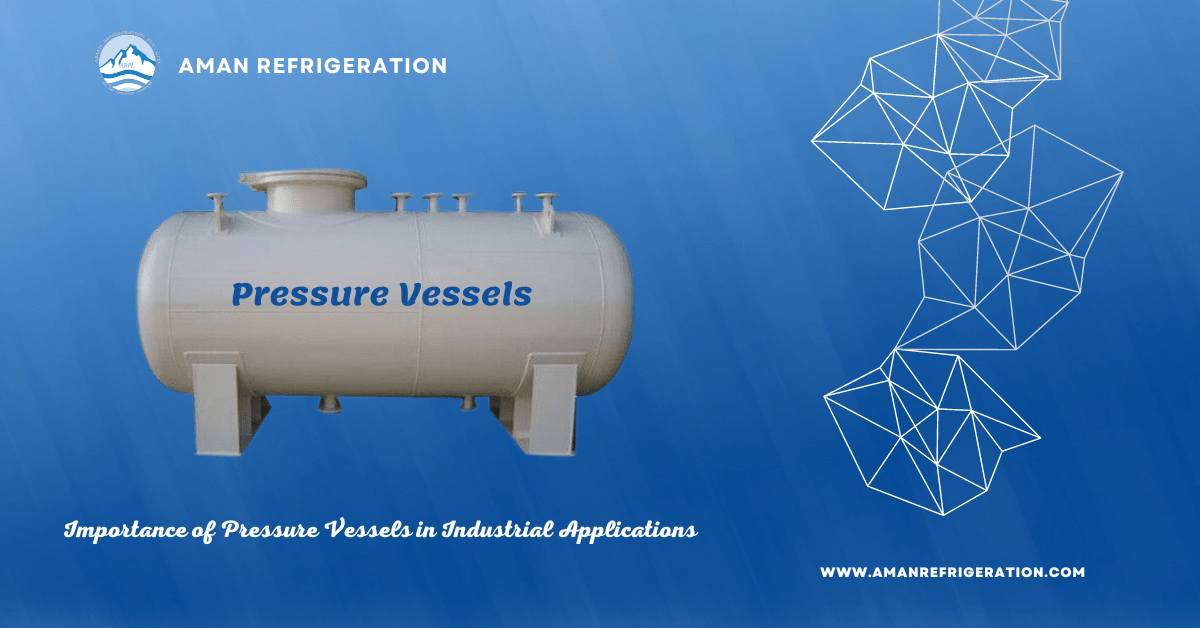

12 Jul What is the important of Pressure Vessels in Industrial Applications?

The Critical Role of Pressure Vessels in Industrial Applications

Pressure Vessels in Industrial Applications play a crucial role in various industrial processes, ensuring the safe and efficient handling of gases and liquids under pressure. These vessels are fundamental components in industries such as chemical manufacturing, oil and gas, power generation, and many more. In this blog post, we will explore the significance of pressure vessels, their applications, benefits, and essential safety measures.

What Are Pressure Vessels?

Pressure vessels are containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. They come in various shapes and sizes, including cylinders, spheres, and cones. The design and construction of pressure vessels are governed by stringent engineering standards and regulations to ensure their safety and reliability.

Applications of Pressure Vessels

1. Chemical Industry

In the chemical industry, pressure vessels are used for storing and processing chemicals under high pressure. They are essential in reactions that require controlled pressure environments to ensure product quality and safety.

2. Oil and Gas Industry

Pressure vessels are critical in the oil and gas industry for the storage and transportation of hydrocarbons. They are used in refineries, petrochemical plants, and offshore drilling rigs to handle fluids at high pressures.

3. Power Generation

In power plants, pressure vessels are used in boilers and reactors to generate steam and electricity. They play a vital role in maintaining the efficiency and safety of power generation processes.

4. Food and Beverage Industry

Pressure vessels are also used in the food and beverage industry for pasteurization and sterilization processes. They help in maintaining the quality and safety of food products by controlling the pressure and temperature during processing.

Benefits of Pressure Vessels in Industrial Applications

1. Efficiency

Pressure vessels are designed to operate at high pressures, which enhances the efficiency of industrial processes. They enable the storage and transfer of large quantities of gases and liquids in a compact space, reducing the need for multiple containers.

2. Safety

Safety is a paramount concern in the design and operation of pressure vessels. They are built to withstand high pressures and temperatures, minimizing the risk of leaks or explosions. Regular inspections and maintenance further ensure their safe operation.

3. Versatility

Pressure vessels are versatile and can be customized to meet the specific needs of different industries. They can be made from various materials, including steel, aluminum, and composites, to handle different types of fluids and pressures.

Safety Measures for Pressure Vessels

1. Design and Construction

The design and construction of pressure vessels must adhere to industry standards and regulations. This includes selecting the appropriate materials, ensuring proper welding techniques, and conducting thorough inspections and testing.

2. Regular Inspections

Regular inspections are crucial to maintaining the safety and integrity of pressure vessels. This includes checking for signs of wear and tear, corrosion, and other potential issues that could compromise their performance.

3. Maintenance and Repairs

Proper maintenance and timely repairs are essential to extending the lifespan of pressure vessels. This includes routine cleaning, replacing worn-out parts, and addressing any defects or damage promptly.

4. Operator Training

Operators must be adequately trained to handle pressure vessels safely. This includes understanding the operating procedures, emergency protocols, and the importance of adhering to safety guidelines.

Conclusion

Pressure vessels are indispensable in various industrial applications, offering efficiency, safety, and versatility. Their proper design, construction, and maintenance are crucial to ensuring the safe handling of high-pressure fluids and gases. By adhering to industry standards and implementing regular inspections and maintenance, industries can maximize the benefits of pressure vessels while minimizing potential risks.

FAQ

Pressure vessels are commonly made from materials like steel, aluminum, and composites, chosen based on the type of fluid and pressure requirements.

Pressure vessels should be inspected regularly, typically at least once a year, depending on the industry and usage conditions.

Common causes of pressure vessel failure include corrosion, material defects, improper maintenance, and operator errors.

Yes, pressure vessels can often be repaired if damaged, but the extent of the damage and the type of vessel will determine the feasibility and safety of the repair.

Industries such as chemical manufacturing, oil and gas, power generation, and food and beverage benefit significantly from using pressure vessels due to their efficiency and safety in handling high-pressure fluids and gases.

No Comments