A Leading Industrial Refrigeration Solution Providing Company

Aman refrigeration- Leading Industrial Refrigeration Solution Providing Company

AMAN REFRIGERATION PRIVATE LIMITED ( An Associate Company of Aman Enterprises incorporated in 2005 ) was founded in 2013 to build chillers and industrial cooling systems primarily for the Food and beverages industry. Aman Refrigeration is a leading name in India’s Industrial refrigeration solution providing company, well-known for its expertise in both Industrial Refrigeration System Solution Provider and also providing top-tier Refrigeration System Maintenance services. With a commitment to excellence and innovation, we provide cutting-edge cooling solutions to a wide range of industries. Our state-of-the-art manufacturing facilities produce cooling towers that are not only highly efficient but also environmental friendly, helping clients reduce energy costs and environmental impact. In addition to our manufacturing process, we take pride in our comprehensive maintenance services, ensuring that your Refrigeration System remains in peak condition. With a team of skilled technicians and a reputation for reliability, Aman Refrigeration is the trusted partner for businesses across India seeking top-tier cooling tower solutions. Experience the difference that expertise and quality make in cooling technology – choose Aman Refrigeration for all your cooling tower needs.

OUR PRODUCTS

Ammonia Refrigaertion is a cost-effective and widely available refrigerant that is popular in many industrial applications such as food processing, cold storage, and ice rinks, due to its high latent heat of vaporization and low boiling point.

Aman Refrigeration Pvt. Ltd indoor air-cooled & Water Cooled industrial chillers are designed for applications in process cooling where it is desirable to convert the heat from Molds, rolls, etc. into hot air to provide facility heat.

Evaporative condensers stand out as the most energy-efficient condensing equipment, harnessing optimal ambient conditions to their fullest extent in order to conserve energy effectively.B.Available in different models starting from 100 kW to 1600 kW heat rejection capacity.

Plate Heat Exchanger facilitates the transfer of thermal energy between two fluids without their direct mixing. It is characterized by its simplicity, compact size, heightened heat transfer efficiency, and easy cleaning and maintenance capabilities.

The function of the High-Pressure Receivers to provide storage for part of the Anhydrous Ammonia liquid inventory needed to supply the plant refrigeration loads, and recirculation receiver loads, as required to maintain efficient operation.

Aman Refrigeration offers horizontal and vertical liquid recirculatory packaged units for both ammonia and halocarbon refrigerants. These packages are factory assembled, pre-wired and pre-piped on a common structural steel.

OUR MISSION

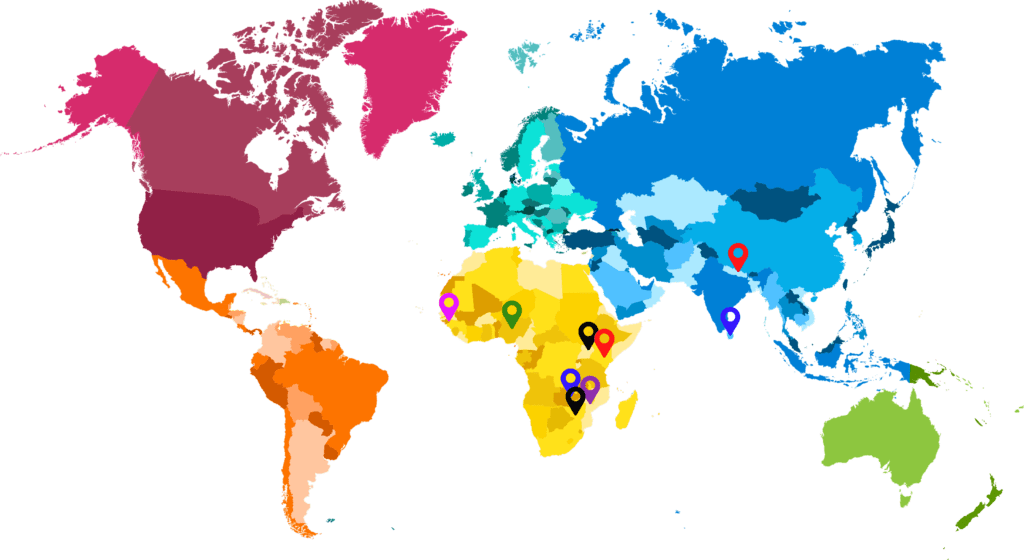

Our mission is to assist customers around the globe in achieving their objectives by delivering unparalleled management solutions for Refrigeartion System, drawing from our top-tier expertise and customized industrial chilling systems.

OUR PROCESS

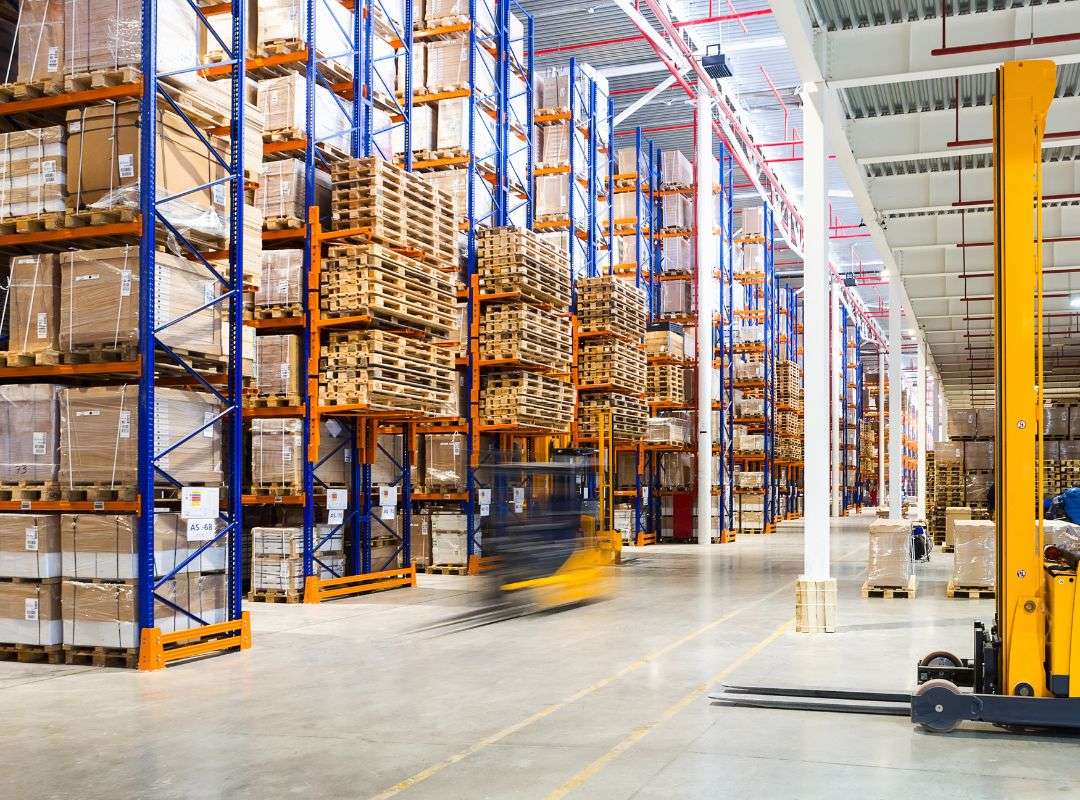

We pride ourselves on simplifying the project for our customers by providing integrated supply capabilities coupled with project management. We have internal capabilities in the design and engineering of Refrigeration System Solution management.

OUR DESIGN DIFFERENCE

Our design difference at AMAN REFRIGERATION sets us apart by combining innovation, efficiency, and tailored solutions to meet your unique cooling needs.

SERVICE ACKNOWLEDGEMENT

Being recognized as a prominent player in our industry, our primary aim is to cultivate enduring partnerships with our clients. Aman Refrigeration’s foundation is rooted in our Refrigeration System Maintenance service.

OUR CUSTOMERS

WHAT OUR CLIENTS SAY

"We're a small business, and we needed a reliable and affordable refrigeration solution. Aman Refrigerator was able to provide us with a custom-designed system that met our needs perfectly. We're very happy with the results, and we would definitely recommend Aman Refrigerator to other businesses."

-Ganesh Singh

"We had a custom cold room built by Aman Refrigerator, and we're very happy with the results. The room is well-insulated and keeps our products cold even in hot weather. The installation process was also very smooth, and the technicians were very professional."

-Ashutosh Dubey

"I'm a refrigeration engineer, and I've worked with Aman Refrigerator on a number of projects. I've always been impressed with their quality products and their commitment to customer service. They're a great company to work with, and I would highly recommend them."

-Aakash Sharma

"We recently had a problem with our ammonia refrigeration unit, and Aman Refrigerator was able to diagnose and fix the problem quickly and efficiently. We were very impressed with their knowledge and expertise, and we would definitely use them again in the future."

-Anil yadav

"I've been using Aman Refrigerator for my commercial refrigeration needs for over 5 years now, and I've been very happy with their products and service. They always deliver on time and within budget, and their technicians are always professional and knowledgeable. I would highly recommend Aman Refrigerator to anyone looking for a reliable and affordable refrigeration solution."

-Gaurav Sharma

Aman Refigration is one of the most well-known and depended on names inside the marketplace when it comes to Industrial Refrigeration Solutions. Our corporation is dedicated to assembly the needs of a wide variety of industries through supplying tremendous refrigeration devices and offerings. We offer many one of a kind styles of cooling structures to satisfy the desires of various industries. These consist of Freon Air and water-cooled refrigeration devices, Ammonia Refrigeration devices, Low-Charge Refrigeration Skids, Evaporative Condensers and near-loop cooling towers, plate warmth exchangers, Pressure Vessels, Mechanical Pump Recirculation Systems, Air Cooling Units, and Automation and Control Panels. All of these are tested to ensure they paintings nicely and are dependable.

India’s businesses rely on powerful and dependable cooling structures to maintain unique goods and methods secure. There are many companies in this area, but Aman Refrigeration often is pleasant at offering commercial refrigeration alternatives. With an extensive variety of merchandise designed to meet extraordinary industry wishes, Aman Refrigeration has come to be the main corporation in India for organizations searching out splendid refrigeration options.

Aman Refrigeration Freon Air & Water-Cooled Refrigeration Units provide businesses with an optimal cooling solution that ensures the preservation of products and maintains the integrity of industrial processes. These units are known for their efficiency, durability, and ability to meet the stringent demands of various industries in India.

At Aman Refrigeration, we take pride in offering state-of-the-art Freon air & water-cooled refrigeration units that are designed to deliver exceptional cooling performance for industrial applications. These units are engineered to meet the highest standards of efficiency and durability, ensuring optimal temperature control for various production processes.

Aman Refigration’s commitment to ecologically sensitive business practises is shown in the Ammonia Refrigeration units‘ ability to provide a cooling solution that is both sustainable and kind to the environment. Because they provide effective cooling while at the same time reducing their total impact on the environment, these units are quickly becoming the commercial sector’s unit of choice in India.

Our dedication to environmentally responsible practises and sustainable practises is evidenced by the ammonia refrigeration units that we offer. We are aware of the significance of using natural refrigerants, and as a result, our products are built to take advantage of the cooling potential of ammonia in a way that is both efficient and respectful of the natural environment.

Ammonia refrigeration valves are used to control the flow of ammonia in refrigeration systems.

Main valves: These valves control the flow of ammonia from the compressor to the evaporator. They are typically pilot-operated valves, which means that a small pilot valve controls the opening and closing of the main valve.

Pressure regulating valves: These valves maintain a constant pressure in the system by controlling the flow of ammonia between the evaporator and condenser.

Liquid flow regulators: These valves maintain a constant flow of liquid ammonia to the evaporator. They are typically used in overfeed systems, where more ammonia is pumped to the evaporator than is needed.

Check valves: These valves prevent backflow of ammonia in the system. They are typically installed in the liquid line between the evaporator and condenser.

In addition to the types of valves listed above, there are also a number of specialty ammonia refrigeration valves available, such as:

Solenoid valves: These valves are electrically operated and can be used to control the flow of ammonia remotely.

Pilot operated check valves: These valves combine the functions of a pilot-operated valve and a check valve.

Multi-function valve stations: These valve stations combine multiple valves into a single unit, which can simplify the installation and maintenance of ammonia refrigeration systems.

Ammonia refrigeration plant accessories are used to support and maintain the safe and efficient operation of ammonia refrigeration systems. : They include a variety of components, such as:

Flanges and fittings: Flanges and fittings are used to connect pipes and fittings together. They are made of a variety of materials, including steel, bronze, and stainless steel.

Pipes and tubing: Pipes and tubing are used to transport ammonia through the refrigeration system. They are made of a variety of materials, including steel, copper, and PVC.

Valves: Valves are used to control the flow of ammonia through the system. They come in a variety of types, including gate valves, globe valves, and butterfly valves.

Pressure gauges: Pressure gauges are used to monitor the pressure in the system. They are typically installed in the suction line, discharge line, and condenser.

Temperature sensors: Temperature sensors are used to monitor the temperature of the ammonia in the system. They are typically installed in the evaporator, condenser, and aftercooler.

Leak detectors: Leak detectors are used to detect ammonia leaks in the system. They can be either electronic or chemical leak detectors.

Safety devices: Safety devices are used to protect the system from overpressure, overheating, and other hazards. Some common safety devices include safety valves, pressure relief valves, and high-temperature cutouts.

Instrumentation: Instrumentation is used to monitor and control the operation of the refrigeration system. This includes devices such as controllers, transmitters, and recorders.

The Low-Charge Refrigeration Skids offered by Aman Refrigeration are created with the intention of offering businesses cost-effective and energy-efficient cooling solutions without sacrificing the level of performance those solutions deliver. Because they provide a straightforward method for cutting down on refrigerant charges, these skids are an invaluable asset for businesses that are working to improve the efficiency of their operations.

The low-charge refrigeration skids offered by Aman Refrigeration provide a solution that is both efficient and cost-effective for businesses and organisations who are trying to reduce the amount of refrigerant they use without sacrificing performance. These skids are designed to provide the highest possible level of cooling while simultaneously minimising their effect on the surrounding environment thanks to our cutting-edge technology.

For better heat removal in many industry processes, our evaporative condensers and closed-loop cooling towers are designed to meet specific needs. Because of the attention paid to reducing the amount of water and energy used in their production, these goods represent an environmentally responsible option for satisfying your requirements for temperature control.

Evaporative condensers and closed-loop cooling towers from Aman Refrigeration are designed to give exceptional heat rejection capabilities, with an emphasis on energy efficiency and water conservation as primary design considerations. These goods not only guarantee excellent cooling performance but also contribute to environmentally responsible business practices within the industrial sector of India.

Plate heat exchangers, such as condensers and evaporators, manufactured by Aman Refrigeration are designed with accuracy and dependability in mind during the manufacturing process. These components play an important part in facilitating heat transfer and maintaining optimal performance in industrial refrigeration systems, which ultimately contributes to an increase in the overall efficiency of a variety of different industrial processes.

Plate heat exchangers from Aman Refrigeration are constructed with precision and quality in mind, and this applies to both the condensers and the evaporators in the set. These components are extremely important in industrial refrigeration systems because of the function they play in enabling heat transfer and assuring top-notch performance.

Our Pressure Vessels are constructed with a strong emphasis on safety and dependability. They are built to endure high pressure and temperature variations, which makes them perfect for a wide range of industrial applications. In order to guarantee the longevity and reliability of our pressure vessels, Aman Refrigeration places a premium on adhering to the highest possible quality standards.

Because of their ability to endure high pressures and varying temperatures, the pressure vessels manufactured by Aman Refrigeration are the product of choice for companies operating in a wide variety of industries in India. These vessels help to ensure the safety and dependability of industrial operations. In the market for industrial refrigeration, the company stands out from the competition thanks to the emphasis it places on quality and endurance.

AMAN REFRIGERATION - OUR PRODUCTS

FREON AIR & WATER COOLED REFRIGERATION UNITS

AMMONIA REFRIGERATION UNITS ( NATURAL REFRIGERATION )

LOW CHARGE REFRIGERATION SKIDS

EVAPORATIVE CONDENSERS & CLOSE LOOP COOLING TOWERS

PLATE HEAT EXCHANGER – CONDENSER & EVAPORATOR

PRESSURE VESSELS

MECHANICAL PUMP RECIRCULATION SYSTEMS

AIR COOLING UNITS

AUTOMATION & CONTROL PANEL

Executed Projects worldwide